Best separation results for weak magnetic material and find iron powder!! |  | |

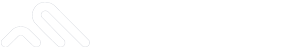

| ■ Main Parameter: The magnetic flux density is at room temperature. *1. Magnetic flux density with no elements (Maximum value) *2. Maximum magnetic flux density when using the standard filter. (Analysis value) There is a weakness depending on the measurement point. *3. Maximum number with standard filter. |  | |

| ■ Filter screen: Filter screen types are usually selected to maximize the magnetic separation capability; however, the screen pitch and quantity can be adjusted based on the material. There are 3 types of standard screens. The standard SUS430 screen enhances corrosionresistance and separation capability. Additionally anti-corrosion and friction reduction processes can be added to the screens. |  | |

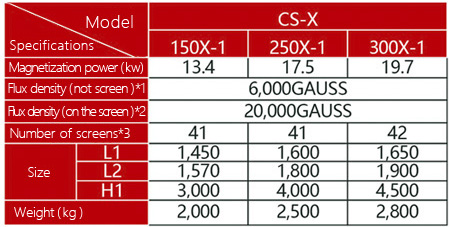

| ■ Example of use: The material can flow from the top to the bottom,but it can also be configured for bottom to top flow for greater efficiency. It can be installed into the existing process line without needing additional pump pressure. Complete filter cleaning requires switching off the power and removing the screen for water or pressure cleaning. |  | |

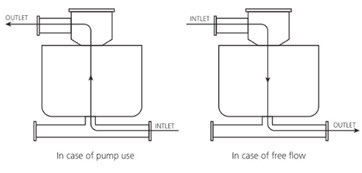

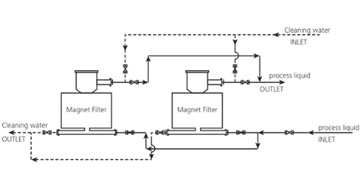

| ■ Continuous Process: Filtered iron particles will clog the screens. Therefore, proper time setting for cleaning or having multiple unit layout will result maximum efficiencies. |  | |

| ■ Full Automation: A combination of timer and automated valve, or a combination of pressure switch and automated valve by using pressure difference of clogging can be used to set up fully automated process. |  |